What’s the difference between spray dyeing and digital textile dyeing? As the textile industry faces increasing pressure to reduce its environmental impact, textile manufacturers are seeking cleaner, more efficient alternatives to traditional dyeing - one of the most resource-intensive and polluting processes in the world. Spray dyeing and digital textile dyeing have emerged as two promising solutions, offering sustainability benefits through reduced water and energy consumption. But how do they stack up against each other? Let’s compare digital textile dyeing to spray.

What’s the difference between spray dyeing and digital textile dyeing? As the textile industry faces increasing pressure to reduce its environmental impact, textile manufacturers are seeking cleaner, more efficient alternatives to traditional dyeing - one of the most resource-intensive and polluting processes in the world. Spray dyeing and digital textile dyeing have emerged as two promising solutions, offering sustainability benefits through reduced water and energy consumption. But how do they stack up against each other? Let’s compare digital textile dyeing to spray.

What is Spray Dyeing?

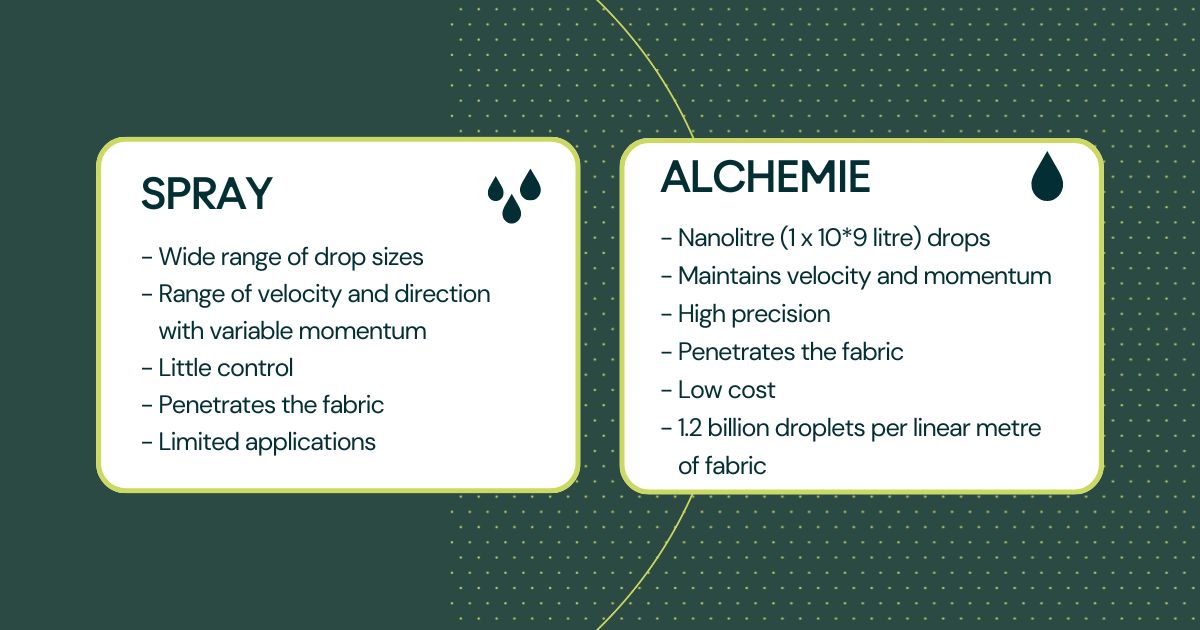

Spray is a method of dyeing textiles. It involves spraying dye onto fabrics – such as cotton or polyester – through precision jets. These jets are positioned at varying distances and angles from the fabric to control dye distribution. The process allows for adjustments in pressure, nozzle size, and airflow, which influence the dye application pattern and coverage. However, achieving consistent and uniform penetration into the fibre remains a challenge, particularly for dense or tightly woven fabrics.

Spray dyeing is commonly used for pigment-based dyes, as they offer better viscosity control and surface adherence. Unlike immersion dyeing methods, pigments do not chemically bond with the fibre and require a binder and curing process to ensure durability. This makes spray dyeing suitable for customised, small-batch production, and patterned or gradient dyeing effects.

While spray dyeing can provide faster application times, it often requires additional drying and curing steps, which may offset the overall time savings compared to traditional dyeing methods. Additionally, colour consistency and penetration can vary, making it less ideal for large-scale uniform production.

Spray Dyeing Application in Textiles

While spray dyeing offers a more water-efficient alternative to traditional dyeing, it comes with significant limitations that affect its industrial scalability.

The variation in droplet size, air pressure, and fabric movement can result in uneven colour coverage, particularly in thicker or highly absorbent fabrics. Unlike digital textile dyeing, where precision droplet control ensures consistent penetration, spray dyeing struggles with fibre saturation, making it less suitable for materials requiring deep-dye penetration.

Additionally, overspray and inconsistent absorption can lead to higher dye waste, reducing the overall efficiency of the process. While spray dyeing generally works best with pigment dyes, which require heat curing rather than water-intensive washing, achieving strong colour fixation and durability remains a challenge.

Although spray dyeing is viable for certain textiles, its inconsistency, scalability limitations, and quality control issues make widespread adoption difficult for large-scale production. For textile manufacturers focused on precision, efficiency, and sustainability, alternative digital dyeing technologies may offer a more reliable and cost-effective solution.

Digital Textile Dyeing: Alchemie’s Technologies

Our digital textile dyeing is a game-changer in the textile industry. Alchemie Technology’s Discovery and Endeavour™ digital textile dyeing solutions offer a breakthrough alternative to traditional and spray dyeing. Unlike spray dyeing, which suffers from inconsistent coverage, high dye waste, and limited scalability, our technology delivers precise, controlled dye application with exceptional efficiency and sustainability.

Through digitally controlled, high velocity nanolitre droplets, our technology ensures deep, even penetration into fabric fibres, eliminating issues like overspray, uneven coloration, and high chemical waste. This level of control matches and exceeds traditional dyeing in terms of colour consistency, while significantly reducing cost, waste, and environmental impacts.

Our technology reduces operational costs (OPEX) by up to 50% and labour costs by up to 60%, offering a scalable, high-performance alternative to traditional and spray dyeing methods. Unlike conventional dyeing, which consumes vast resources and generates pollution, Alchemie’s digital dyeing technology achieves superior efficiency while slashing water, chemical, and energy waste.

Key Benefits of Alchemie’s Digital Dyeing Technology

Unmatched Water Savings

Traditional dyeing consumes up to 200 litres of water per kilogram of fabric, while spray dyeing still requires post-treatment washing. In contrast, Alchemie’s waterless digital dyeing process eliminates the need for large water baths, cutting wastewater pollution by up to 95%. This not only reduces operational costs but also aligns with global sustainability goals.

High Precision, Low Chemical Waste

Unlike spray dyeing’s inconsistent application and pigment limitations, our technology supports a wide range of dyestuffs - including reactive, acid, and disperse dyes - with exceptional precision. Our system applies 1.2 billion droplets per linear metre, reducing chemical waste by up to 30% and ensuring minimal dye loss and contamination.

Energy Efficient Textile Production

Alchemie’s fully electric dyeing process significantly reduces energy consumption and CO₂ emissions by up to 85%, compared to traditional thermal-based dyeing. Our Discovery system enables rapid colour development, dyeing 5 metres of fabric per minute, while our production-scale Endeavour™ system processes up to 15 metres per minute - making it the most scalable and sustainable solution available. Therefore, through transitioning from energy intensive traditional dyeing to electrification, you will reduce your CO2 emissions by up to 85%, aligning sustainability goals with production demands.

A Game-Changer for the Textile Industry

Unlike spray dyeing, which remains limited in fabric penetration and large-scale adoption, Alchemie’s digital textile dyeing is a commercially proven, industrial-scale solution. Our Discovery system enables rapid lab trials, ensuring precise colour development before scaling up to full production runs on our Endeavour™ system. With superior sustainability metrics, lower costs, and unmatched precision, our technology is the future of textile dyeing - offering brands and textile manufacturers a viable path to truly sustainable production.

Ready to transition to the textile factory of the future? Then discuss with us at - enquiries@alchemietechnology.com