Do you know the difference between Alchemie's technologies vs inkjet? With the textile industry rapidly evolving and demanding more sustainable textile dyeing practices, innovations such as digital textile dyeing are fast becoming the solution to choose. Compatible with fabric-specific dyes, customisation capabilities, and sustainability benefits, you can see why brands and textile manufacturers are transforming their processes.

Explore the similarities and differences between inkjet printing and digital textile dyeing and how they contribute to sustainable textile production within the textile industry.

Understanding what is inkjet printing and digital textile dyeing

Inkjet printing and digital textile dyeing are distinctly different, particularly in their purpose and applications. However, they do share similarities in their use of digital technology.

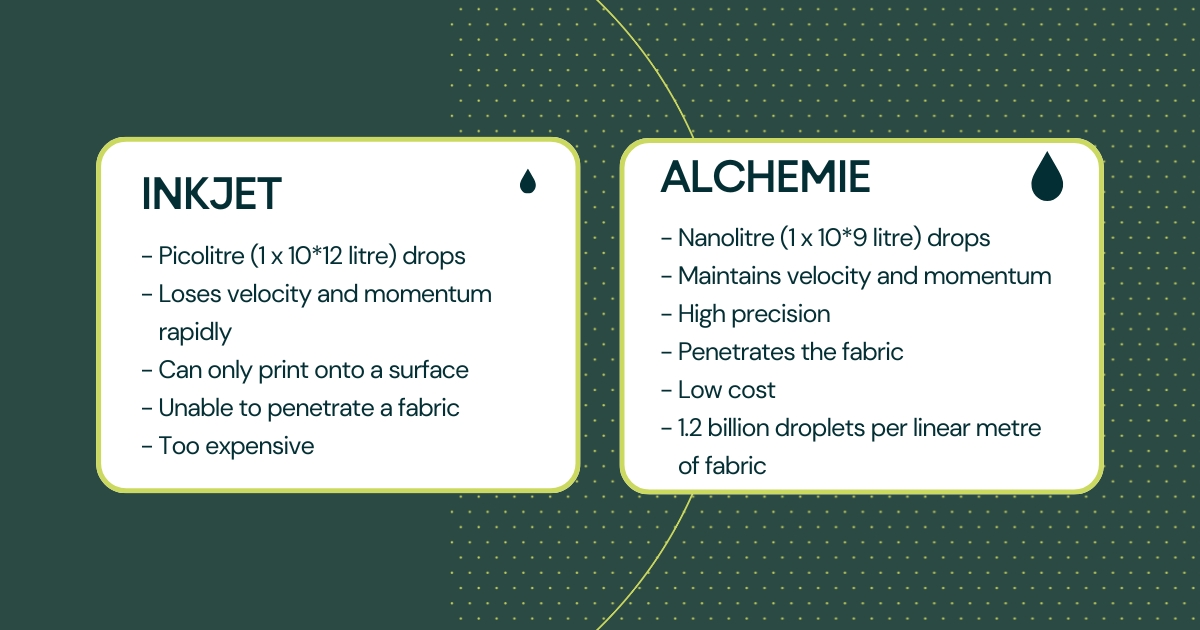

- Inkjet printing – a technology commonly associated with printing onto paper or non-textile surfaces. However, inkjet printing can adapt to textiles, by spraying picolitre droplets of ink onto fabrics, creating intricate designs.

- Digital textile dyeing – a specialised dyeing process that is tailored for textiles. It involves dyeing onto fabrics with dyestuffs that are specifically designed for durability, colour fastness, vibrancy, and compatibility with various fabrics.

What are the differences between inkjet printing and digital textile dyeing?

Inkjet printing and digital textile dyeing perform differently in relation to application and scope, fabric compatibility, production efficiency, and environmental impact.

Application and scope

Inkjet printing was first developed for paper, however, it has been adapted for a wide range of surfaces, including textiles due to applying the Direct-to-Garment (DTG) method. Whereas digital textile dyeing is designed especially for dyeing onto fabrics. Digital textile dyeing is tailor-made for textile production across sectors such as fashion & apparel, home textiles, and sportswear to name a few.

Fabric compatibility

As for compatibility with different fabrics, inkjet printing is adaptable but requires adjustments for optimal fabric performance. Digital textile dyeing, on the other hand, is compatible with a wide range of fabrics, including cotton, polyester, cellulosics, and blends. Digital textile dyeing also caters for textile-specific dyes like reactive, acid, pigment, and disperse dyes, ensuring the highest quality results throughout.

Production efficiency

Both technologies have their own niche when it comes to production. Inkjet printing is best suited for small-scale production and prototyping but has limited scalability for large-scale continuous dyeing due to speed constraints and necessary fabric treatments. Meanwhile, digital textile dyeing efficiently handles both small and large production volumes, making it ideal for on-demand manufacturing. By enabling precise dye application, it reduces inventory waste and improves sustainability.

Environmental impact

Inkjet printing and digital textile dyeing share a “dry process” whereby they do not use water-dominant inks or dyes respectively. In turn, they significantly reduce dependence on water sources during printing or dyeing, especially when compared to traditional textile dyeing methods. From this, inkjet printing has a lower environmental impact on small-scale applications, typically used for prototyping or heat transfer designs.

Opposingly, digital textile dyeing solutions cater for small- to large-scale sustainable textile dyeing, courtesy of the precise dye application to minimise waste, capable of aligning with sustainability goals such as ESG (Environment, Social, Governance) and other international regulations.

Inkjet printing: Limited role in textiles

Although inkjet printing has a lower environmental impact for small-scale applications, its role in textiles is limited due to several challenges: specialisation, durability, and niche use. Inkjet printing requires significant adaptation for fabrics, making it less suitable for large-scale production.

Digital textile dyeing: Our technologies

Digital textile dyeing: Our technologies

Born out of inkjet, our digital textile dyeing machines – Discovery and Endeavour™ – use digital technology to dye fabrics. With over 10 years of innovation behind them, our technologies have been developed to be the industry-leading digital textile dyeing solution. Using our unique nozzle technology, specifically designed and adapted for textile dyeing, we combine a nanolitre droplet size and high droplet velocity to deliver unrivalled penetration into the textile.

In turn, Alchemie’s digital textile dyeing offers high efficiency for both small and large production runs and seamless integration into your current process, courtesy of our lab system Discovery and production system Endeavour™. Through these digital textile dyeing machines, you have clean-technology solutions for a modern working environment, allowing you to produce at scale and meet your evolving textile production demands.

Building a sustainable future

While inkjet has its merits, digital textile dyeing is a transformative solution designed especially for the textile industry with brands, textile manufacturers, and organisations throughout the supply chain in mind. Using our technologies, we provide you with small- to large-scale production systems, that interweave with global sustainability goals (such as ESGs) and evolving industry demands and regulations. Our ability to combine customisation, efficiency, and environmental responsibility makes our technologies indispensable for the modern textile dyeing industry. Together, we can lead the way towards a more sustainable textile industry.

Brands, what textile dyeing processes do you use? Discuss with us: enquiries@alchemietechnology.com